- We succeed where others fail!

- 860.564.7817

- Email Us

Thermoset Epoxy Adhesives

- Home

- Thermoset Epoxy Adhesives

An Overview of Thermoset Epoxy Adhesives

At Adhesive Prepregs for Composite Manufacturers (APCM), we are one of the industry leaders in prepreg manufacturing. We specialize in the development of prepreg made with thermoset epoxy.

The term “epoxy”—also referred to as “epoxy resin” or “epoxide”—encompasses a collection of reactive compounds characterized by an oxirane (or epoxy) ring—consisting of an oxygen atom bonded to two carbon atoms—present in their molecular composition. While all epoxies must contain the distinct chemical ring, they can vary significantly in regard to their molecular structures to suit different applications.

Epoxy resins first entered commercial production in the late 1940s. Since then, they’ve expanded to include a wide range of materials, each of which offers different performance characteristics (e.g., strength, versatility, and adhesion). A common form of epoxy resins is epoxy adhesives, of which thermoset epoxy adhesives are one of the main varieties. Below we provide an overview of these unique materials, outlining what they are and why they are important to prepreg production applications.

What Are Thermoset Epoxy Adhesives?

Polymerization is key to the application of epoxy adhesives. The process involves mixing the resin material with a specific catalyst (depending on the resin’s composition) to initiate curing. Curing the resin improves its strength and rigidity, ensuring its forms a strong and durable bond with the base substrate. The exact choice of resin and catalyst—as well as the curing conditions (e.g., temperature)—influence the characteristics of the adhesive bond achieved. As such, it is essential to carefully match the type of resin and catalyst and curing conditions to the needs of the application.

Thermoset epoxy relies on heat or radiation as the curing catalyst. In contrast to thermoplastics, the hardening of thermosets is irreversible as the process changes their chemical and physical structures.

The Role of Thermoset Epoxy Adhesives in Prepreg Production

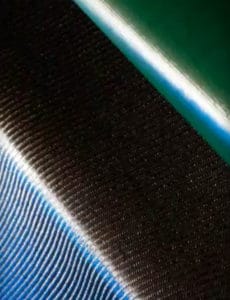

The term “prepreg” refers to fabrics and other fiber-based materials that are reinforced by pre-impregnating them with resin. The resins used for the production of these materials are generally epoxy resins, as they offer simple curing requirements, broad compatibility with a variety of substrates, and good wetting properties.

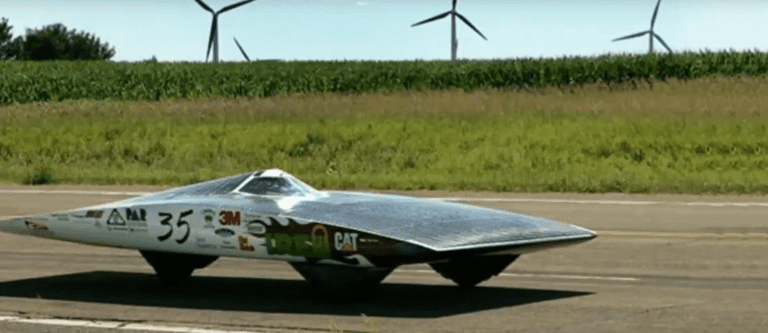

When choosing the type of resin to use in prepreg production operations, it is vital to consider the attributes necessary for the intended application. While both thermoplastic and thermoset epoxy resins are used in the production of prepreg composites, thermoset variations are generally the first choice of manufacturers. Their popularity stems from their superior structural integrity and resistance to deformation, harsh chemicals, and extreme temperatures when cured, all of which result in greater durability and reliability in the finished product.

Contact the Thermoset Epoxy Prepreg Experts at APCM Today

Thermoset epoxies are unique materials that play a critical role in prepreg production. If you want to learn more about them, turn to the experts at APCM.

At APCM, we’ve manufactured high-quality thermoset epoxy prepregs for composite part designers, manufacturers, and hobbyists for over 20 years. This experience enables us to develop lighter, stronger, and faster-performing prepregs for a wide range of customer needs. For more information about our prepreg capabilities, contact us today.

// Prepregs Products

APCM, LLC. the company, we help make our customers