- We succeed where others fail!

- 860.564.7817

- Email Us

Prepreg Carbon Fiber

- Home

- Prepreg Carbon Fiber

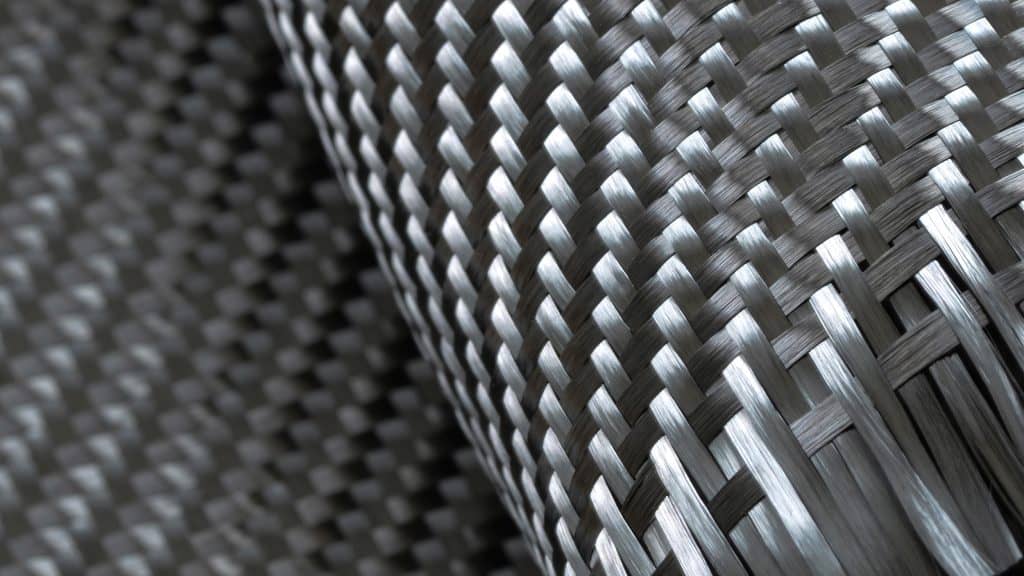

Carbon fiber is an important material in many industries, offering the strength to replace metal despite its low weight and excellent formability. However, carbon fiber is not a single material. Different composites feature very different weave patterns and can be prepared with varied processing methods.

Prepreg carbon fibers are those that have already been pre-impregnated with resin before they ship to clients. This simplifies the molding process and yields a material that, once cured, is lightweight, durable, and highly temperature-resistant. These composites offer impressive performance characteristics that justify their use in aircraft, sports cars, prosthetics, and other demanding applications.

What is Prepreg Carbon Fiber?

Carbon fiber is a strong, durable material composed of carbon-based crystalline fibers. These fibers are bundled together, then either woven together into a fabric or used directly to reinforce a polymer matrix. In either case, carbon fibers are usually used as part of a composite, which combines the carbon fibers with resin. Bonding carbon fibers with resin creates a strong, stiff composite that can replace metal in many industrial settings. Carbon fiber composites can have twice the strength of steel at just 25% of its weight, so they are excellent alternatives in automotive, aerospace, and other weight-sensitive applications.

Prepreg carbon fiber specifically refers to a carbon fiber fabric that has been pre-impregnated with resin before it ships. The most common choice is epoxy resin, a versatile plastic with favorable compressive and shear properties. However, prepreg materials may contain different types of resins distributed in different ratios. They may also feature different fiber configurations, including both woven and non-woven arrangements. These variables influence the weight and performance characteristics of the final composite.

Prepreg carbon fiber is extremely easy to work with. Manufacturers can easily cut, bend, and form a prepreg to achieve their desired shape. Depending on the exact resin used, curing the material typically requires a combination of heat and pressure.

A-Stage & B-Stage Prepreg Carbon Fiber

Curing a thermoset resin composite proceeds in three stages. Typically, prepregs are shipped at the B stage, which influences how the materials should be handled, stored, and formed.

- A Stage. The first step is simply to mix the resin and curing agent. At the A Stage, the actual chemical reaction has not yet begun.

- B Stage. At the B Stage, the curing reaction has begun, but the material has not completely hardened. Since different resins have different curing methods, this stage may begin in different ways. For example, in a solvent-based curing system, applying heat will remove some of the solvent and begin the curing process. At this point, the mixture has thickened and become tackier, but it has not completely cured. By freezing the material this will halt the B stage system to be cured at a later time.

C Stage. At the C Stage, the resin has completely cured. For many thermoset resins, this requires the use of an oven or autoclave.

Types of Carbon Fiber Weaves

Woven vs. Unidirectional Carbon Fiber

Carbon fiber materials can be categorized as either woven or unidirectional, depending on how they are formed. Unidirectional carbon fiber is non-woven, so it does not have any weave pattern. Instead, its fibers lie parallel to one another with no gaps. This method of construction maximizes longitudinal tensile potential, so it is ideal for applications requiring strength in a single direction. However, many applications subject composite materials to multidirectional tensile forces. Woven carbon fibers are more appropriate for these applications. Woven fabrics also tend to be more workable and machinable than unidirectional fiber.

Common Weave Patterns

Woven carbon fiber materials can be further classified based on their weave, or the pattern used to join fibers into a fabric. These differences are not purely aesthetic—different weaves look very different from one another, but they also have distinct performance characteristics. Accordingly, some weaves are more appropriate for certain applications than others.

First, the fibers are bundled into groups called tows, 3K and 12K are standard industry fiber bundles which are 3,000 and 12,000 fibers densely packed together. The way these tows are combined determines the fabric’s strength, stability, and formability.

- Plain Weave. The simplest carbon fiber weave is known as a plain weave. The plain weave is formed by crossing tows in a one-over, one-under pattern, creating the checkerboard seen on many woven fabrics. These materials are strong and highly stable, but they are not very pliable. Plain woven carbon fiber is best for components that are flat or only slightly contoured.

- Twill Weave. Like the plain weave, the twill weave comes from passing tows in an even over/under pattern. However, rather than passing over a single tow, each strand passes over multiple tows, then under the same number of tows. This is typically done in a two-over, two-under pattern, but 4 x 4 twills are also common. In either case, the resulting pattern appears to form rows of rectangles proceeding diagonally up the fabric. Twill weaves are more formable than plain weaves, so they can be used with more complex shapes. However, this means that they are not as stiff and stable as plain weaves.

Spread Tow Weaves

“Spread tow” does not describe a specific weave pattern. Instead, it refers to fabrics woven with wider, thinner tows than usual, which can be combined into the weave patterns described above. These “spread tows” create smoother, lighter weight fabrics because they spread stress more evenly than standard tows. Any woven fabric has a crimp angle, which is the angle formed at the intersection of fibers. Stress can become concentrated at these intersections, changing the strength of the fabric. Spreading the tows creates shallower crimps that accumulate less stress.

Prepreg Carbon Fiber Applications

Prepreg materials are easy to work with while offering highly favorable mechanical properties. They can also be safer and more friendly than other resin methods. Carbon fiber prepregs, in particular, are known for their strength, stiffness, and resistance to both chemicals and extreme temperatures. These properties, coupled with carbon fiber’s extremely light weight, benefit both military and industry applications, including:

- Aircraft interiors

- Aerospace components

- Shielding and reinforcements

- Cargo liners and airplane flooring

- High-end automotive parts and components

- Electrical vehicle and drone components

- High-temperature components

- Prosthetics and medical devices

The team at APCM can help you determine which prepreg is the best match for your application.

APCM’s Premium Prepreg Materials

APCM has been a leading provider of prepreg composites for nearly three decades. Our carbon fiber prepregs are easy to work with while still offering the strength, durability, and reliability clients expect from carbon fiber composites. APCM is committed to meeting clients’ needs, no matter what their industry or capacity. We offer rolls, sheets, and pre-cut segments and fulfill orders of all sizes. Whether you’re a hobbyist seeking a single roll or a fabricator seeking a high volume of custom material, we will work to accommodate your needs. To learn more about our high-performance carbon fiber prepregs, contact us today.

// Prepregs Products

APCM, LLC. the company, we help make our customers